Domestic EDA has been exploring and advancing in the ups and downs for a long time. Even though the domestic EDA industry has achieved some achievements, there is still a gap from the international leading firms. There are three main aspects of the gap: (1) Lacking of critical tool module of digital chip designing, unable to support the whole process design of digital chip; (2) Insufficient support for advanced process technology node, only few tools have capability to support 14nm, 7nm, 5nm technology node. (3) Insufficient investment in technology. (4) Insufficient investment in capital. The specific introduction is as follows.

1) The product is not complete enough, especially in the digital circuit, the overall system lacks digital chip design core tool module, and cannot support the full design flow.

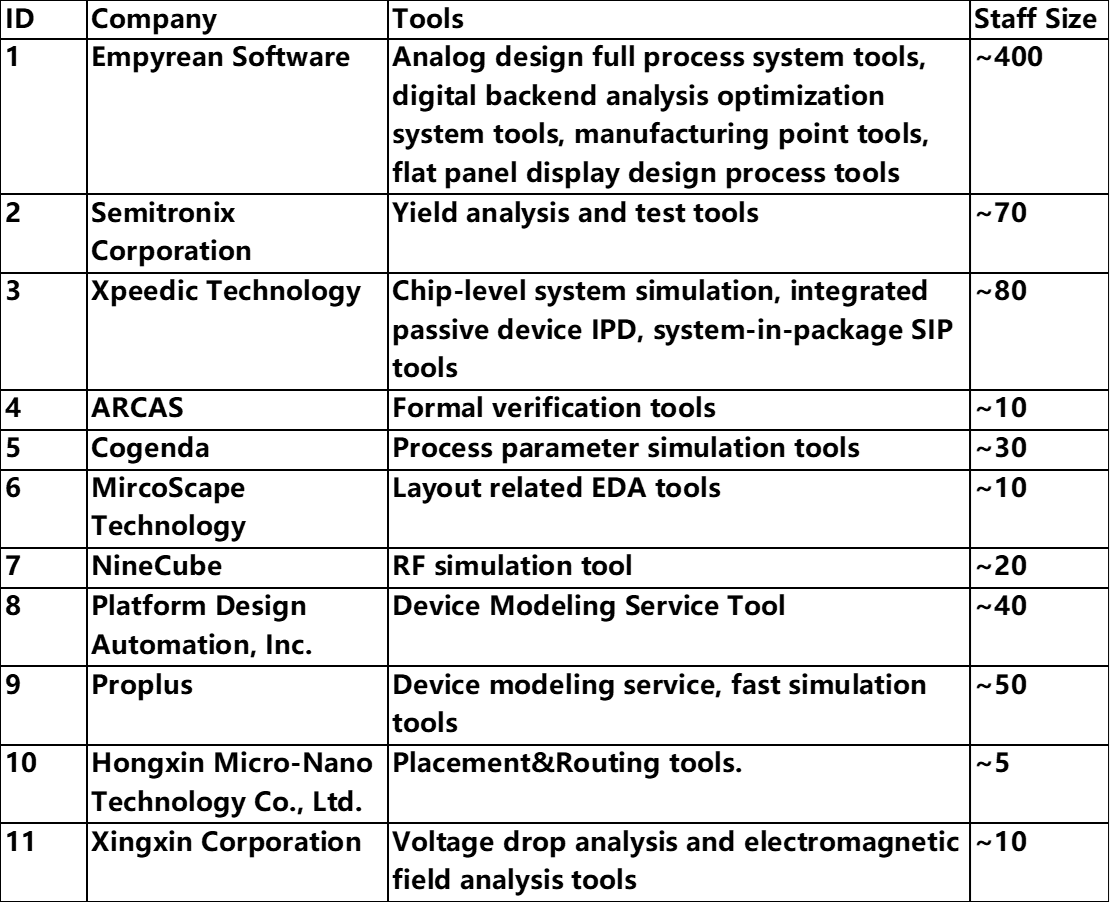

Take Empyrean as an example. They only make one-third of the products in this digital circuit field, and two-thirds need make up. An important reason for this situation is that there are not enough engineers to support all-round research and development. Experts from industry, academia and research circles have reached consensus that if China wants to make the whole set of EDA tools, it is not about individual domestic manufacturer, but needs a variety of cooperation.

2) Because of the lacking of integration with advanced technology, domestic EDA tools are not enough for advanced process support.

In the modern integrated circuit industry, the bridge between chip design and manufacturing is very important, EDA plays such a role of bridge. However domestic enterprises have two insurmountable gaps in this docking: on the one hand, domestic EDA vendors have few opportunities to access advanced technologies, which limits their technological advancement. It is understood that the world's leading fabs, such as TSMC and Samsung, will first introduce international cash companies such as Cadence and Synopsys to develop new technologies. Domestic EDA vendors are not valued. They are unable to obtain relevant support from foreign manufacturers. In the long run, the gap between the technology accumulation of domestic EDA companies and international advanced companies will gradually expand.

On the other hand, the shortcomings of the domestic industry in the PDK (Process Design Kit) also has some negative effects on the development of domestic EDA. The PDK contains various documents related to process and device. It is the key to the successful production of the designed chip in the fab. It is the bridge between the IC design company, the foundry and the EDA manufacturer. The lacking of PDK in domestic manufacturers has affected the development of the domestic EDA industry to some extent.

3) Insufficient investment in professional talents

The shortage of professional talents is a key factor limiting the development of domestic EDA. The weak R&D team is difficult to support the massive task of attacking. The root cause of this appearance is the industry's insufficient investment in EDA. There are about 1,500 EDA software development engineers in China, but the number of engineers working in local EDA companies and research units add up to less than 300. Most of the others work in the three international giants. And looking at the global market, comparing to Synopsys with more than 7,000 R&D employees (over 5,000 engaged in EDA, others focused in IP), the gap is even more significant.

4) Less investment in R&D

Among the current local EDA companies, even the largest team and the longest-established firm Empyrean, they have spent only a few hundred million yuan on R&D in the past decade. While foreign advanced competitors invest billions of yuan each year in product research and development (Synopsys' R&D investment in 2017 is about 810 million U.S. dollars, and in 2018 it is more than 1 billion U.S. dollars). Compared with this huge number, domestic EDA company's research and development funds is almost negligible. If domestic EDA wants to further develop, it is imperative to increase capital investment.